Global Sandwich Panels Market to Reach USD 33.7 Billion by 2035, Expanding at 5.7% CAGR | Transparency Market Research

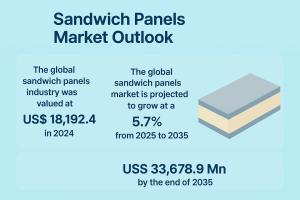

The global sandwich panels market is set to grow from US$ 18.19 Bn in 2024 to US$ 33.68 Bn by 2035, expanding at a CAGR of 5.7% during 2025–2035.

Demand for lightweight, thermally efficient materials is driving sandwich panel adoption across industrial, commercial, and emerging residential projects.”

WILMINGTON, DE, UNITED STATES, October 8, 2025 /EINPresswire.com/ -- The global sandwich panels market has emerged as a crucial segment within the construction and insulation materials industry, owing to the increasing demand for durable, energy-efficient, and lightweight building solutions. In 2024, the global industry was valued at US$ 18,192.4 Mn, and it is projected to grow at a CAGR of 5.7% from 2025 to 2035, reaching a value of US$ 33,678.9 Mn by the end of the forecast period.— Transparency Market Research

The continuous shift toward sustainable and high-performance building materials, combined with the surge in construction activities across industrial, commercial, and residential sectors, has significantly boosted the adoption of sandwich panels. These panels consist of two outer metal sheets enclosing a core made of insulating material such as polyurethane (PUR), polyisocyanurate (PIR), expanded polystyrene (EPS), or mineral wool, offering superior thermal, acoustic, and mechanical properties.

Full Market Report available for delivery. For purchase or customization, please request here –

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=78991

Analysts’ Viewpoint

According to industry analysts, the sandwich panels market is primarily driven by the rising demand for thermally efficient and lightweight materials in construction and industrial applications. The construction of warehouses, cold storage facilities, clean rooms, and prefabricated buildings is expanding rapidly, creating consistent demand for sandwich panels.

The preference for PUR and PIR cores is particularly notable due to their outstanding thermal insulation and fire resistance properties. In contrast, EPS and mineral wool panels are more cost-effective options used in projects where specific fire, sound, or moisture resistance characteristics are prioritized.

Cold storage and industrial applications dominate market demand, fueled by growth in food processing, pharmaceuticals, and logistics sectors, all of which rely on temperature-controlled environments. The commercial segment—comprising office buildings, malls, and institutional projects—ranks next, while the residential sector is steadily gaining traction with the increasing popularity of modular and prefabricated housing.

Regionally, Asia Pacific leads the global market, supported by rapid industrialization, infrastructure development, and favorable government policies promoting energy-efficient construction. The market remains multifaceted, with applications spanning across industrial, commercial, and residential projects.

Introduction to Sandwich Panels

Sandwich panels are composite materials designed to offer both structural and insulation benefits. They consist of two rigid outer layers, typically made from galvanized steel, aluminum, or fiber-reinforced plastic, enclosing an insulating core material that can be made of PUR, PIR, EPS, or mineral wool.

Their layered configuration provides several advantages:

• High thermal and sound insulation

• Lightweight yet strong structural integrity

• Quick installation and easy maintenance

• Resistance to fire, moisture, and corrosion

These characteristics make sandwich panels ideal for a wide range of applications including roofing, wall cladding, cold storage rooms, truck trailers, shipping containers, and clean-room facilities. The versatility of sandwich panels also allows customization in thickness, core material, and surface coating to meet diverse architectural and industrial requirements.

With increasing emphasis on energy efficiency and sustainability, sandwich panels are replacing conventional construction materials such as brick, concrete, and wood. Their ability to reduce energy consumption in temperature-controlled environments and maintain stable indoor climates aligns perfectly with modern green building trends.

Market Dynamics

Key Market Drivers

1. Increasing Usage in Cold Storage and Temperature-Controlled Facilities

The global demand for cold storage infrastructure has surged dramatically due to the expansion of food processing, pharmaceutical, and e-commerce industries. Sandwich panels are preferred materials in cold rooms, refrigerated warehouses, and transport containers due to their excellent thermal insulation and lightweight structure.

As supply chains become increasingly global and temperature-sensitive goods such as vaccines, frozen foods, and biologics demand precise climate control, the role of sandwich panels becomes indispensable. Their quick assembly, modularity, and cost-effectiveness allow construction of large-scale cold storage facilities in shorter timeframes, significantly lowering capital and operational costs.

Furthermore, these panels offer superior fire and moisture resistance, which ensures safety and reduces spoilage risks in temperature-controlled environments. The exponential growth of online food delivery, perishable goods trade, and global pharmaceutical logistics is expected to keep cold storage construction robust, directly propelling the sandwich panels market forward.

2. Rising Demand for Energy-Efficient and Sustainable Buildings

Sustainability has become a defining feature of modern construction practices. Governments, corporations, and consumers are increasingly prioritizing energy-efficient buildings that align with global carbon reduction targets. Sandwich panels, particularly those using PUR and PIR cores, significantly reduce heating and cooling requirements by maintaining stable indoor temperatures.

These insulation properties directly contribute to lower energy bills and reduced greenhouse gas emissions. The European Union’s Energy Performance of Buildings Directive (EPBD), for instance, mandates improved insulation standards, encouraging wider adoption of materials like sandwich panels. Similar green building regulations in North America, China, and the Middle East are reinforcing this trend.

Beyond energy performance, sandwich panels also enhance occupant comfort by stabilizing temperature fluctuations and providing soundproofing advantages. Their long-term durability and recyclability make them a viable solution for sustainable architecture and green certifications.

Market Challenges

While the market outlook remains positive, a few challenges persist:

• High initial installation costs compared to conventional materials in developing countries.

• Fluctuations in raw material prices, especially steel and polyurethane.

• Regulatory complexities regarding fire safety standards and insulation performance in different regions.

Nonetheless, ongoing R&D in eco-friendly core materials, bio-based polyurethane, and recyclable aluminum cladding is expected to mitigate these issues over time.

Segment Analysis

By Core Material

• Polyurethane (PUR): PUR dominates the market due to its superior thermal insulation, lightweight properties, and cost-effectiveness. It provides better insulation performance than EPS or mineral wool at thinner thickness levels, reducing overall construction weight and costs. Its low water absorption and durability make it suitable for cold storage and industrial applications.

• Polyisocyanurate (PIR): PIR panels are an upgraded version of PUR, offering enhanced fire resistance and insulation properties. However, their higher cost limits adoption to projects with stringent performance specifications.

• Expanded Polystyrene (EPS): EPS panels are cost-effective and lightweight but offer lower fire resistance and moisture protection compared to PUR or PIR. They are used in budget-sensitive projects or in climates with moderate temperature variations.

• Mineral Wool: Mineral wool panels offer excellent fire resistance and soundproofing, making them ideal for industrial buildings and manufacturing plants. However, their higher weight and cost restrict usage in some regions.

Overall, PUR panels remain the most preferred material, striking a balance between cost, performance, and versatility.

By Application

• Wall Panels: Widely used for exterior and interior wall cladding due to excellent insulation and aesthetic appeal.

• Roof Panels: Common in industrial and warehouse buildings where thermal control is essential.

• Floor Panels: Increasing adoption in cold rooms and clean rooms requiring specific temperature control and load-bearing capabilities.

By End-use Sector

• Industrial Buildings: The largest consumer segment due to demand from manufacturing facilities, logistics hubs, and warehouses.

• Commercial Buildings: Includes malls, offices, and institutional structures prioritizing aesthetics and energy efficiency.

• Residential Buildings: A growing segment supported by modular housing and prefabricated construction trends.

• Others: Agricultural structures and temporary shelters, especially in remote or disaster-prone areas.

By Thickness

Sandwich panels are available in various thickness categories such as below 60 mm, 60–100 mm, 100–140 mm, 140–180 mm, and above 180 mm, depending on thermal insulation requirements. Thicker panels are typically used in cold storage and industrial applications, whereas thinner ones suffice for residential and commercial construction.

Regional Outlook

Asia Pacific – The Dominant Market

Asia Pacific holds the largest share in the global sandwich panels market, driven by urbanization, industrial expansion, and infrastructure development across countries such as China, India, Japan, and Southeast Asia.

This region benefits from:

• Rapid construction of warehouses, industrial parks, and housing complexes.

• Availability of low-cost raw materials and labor.

• Government initiatives promoting energy-efficient and sustainable construction.

The cost competitiveness of regional manufacturers has enabled Asia Pacific to become both a production and export hub for sandwich panels. Furthermore, smart city projects, industrial corridors, and housing development programs continue to boost product demand.

Europe and North America

Both regions have mature construction markets but continue to witness demand for high-performance insulation materials due to strict energy efficiency regulations. The EU’s sustainability policies, and U.S. Green Building Council (USGBC) initiatives, ensure continued utilization of sandwich panels in retrofitting and new builds.

In Europe, companies like Kingspan Group and Metecno Group are leading innovators, focusing on advanced fire-rated and eco-friendly panel systems. Meanwhile, in North America, demand is supported by investments in logistics warehouses, temperature-controlled distribution centers, and commercial retrofitting projects.

Middle East & Africa and Latin America

These emerging regions are expected to register strong growth due to infrastructure modernization, industrial expansion, and construction of energy-efficient facilities. Countries in the Gulf Cooperation Council (GCC) are investing heavily in industrial complexes, smart cities, and logistics hubs, thereby generating demand for durable building materials such as sandwich panels.

In Latin America, particularly in Brazil and Mexico, growing adoption of prefabricated construction systems is fostering market expansion.

Competitive Landscape

The sandwich panels market features a competitive mix of global giants and regional manufacturers, emphasizing product innovation, energy efficiency, and cost optimization. Major players include:

• ArcelorMittal

• Areco Group

• Assan Panel A.S.

• Avient Corporation

• Balex-Metal

• DANA Group of Companies

• Kingspan Group

• Manni Group S.p.A.

• Metecno Group

• Nucor Corporation

• Romakowski GmbH & Co. KG

• Tata Steel

• Rinac India Ltd.

These companies focus on expanding production capacities, developing eco-friendly core materials, and entering strategic partnerships to strengthen market presence.

Recent Developments

• June 2025: Rinac India Limited partnered with Epta Group to enhance India’s cold chain infrastructure, integrating Epta’s refrigeration technology with Rinac’s domestic expertise and service network.

• April 2025: Kingspan Group initiated construction of a €280 Mn Building Technology Manufacturing Campus near Lviv, Ukraine, to boost its sandwich panel production capacity and foster innovation in energy-efficient materials.

Such initiatives reflect the industry’s commitment to sustainability, regional expansion, and technological advancement.

Future Trends and Opportunities

1. Adoption of Green and Bio-based Materials: Manufacturers are investing in sustainable raw materials and recycling technologies to align with global environmental targets. Bio-based polyurethane foams and recyclable aluminum skins are gaining popularity.

2. Digital and Modular Construction: The rise of Building Information Modeling (BIM) and prefabricated modular designs promotes the use of sandwich panels for faster, safer, and more efficient construction.

3. Integration of Smart Technologies: Advanced sandwich panels incorporating sensors for temperature, humidity, and fire detection are being developed, especially for critical storage and industrial applications.

4. Growing Infrastructure Investment in Emerging Economies: Developing regions in Asia, Africa, and Latin America are investing heavily in industrialization, offering enormous potential for sandwich panel manufacturers.

The global sandwich panels market is poised for significant expansion through 2035, driven by the growing need for energy-efficient, durable, and lightweight construction materials. With the market projected to reach US$ 33,678.9 Mn by 2035, manufacturers and stakeholders are expected to capitalize on the growing adoption of prefabricated, thermally insulated, and sustainable building systems.

The future of the sandwich panels industry lies in innovation, sustainability, and strategic partnerships, aligning perfectly with the global shift toward smart, green, and cost-effective infrastructure solutions.

As construction paradigms evolve, sandwich panels will remain a cornerstone material—bridging efficiency, durability, and environmental responsibility across the built environment.

Access More Trending Exclusive Reports by Transparency Market Research:

Boranophosphates Market: https://www.transparencymarketresearch.com/boranophosphates-market.html

Transparent Ceramics Market: https://www.transparencymarketresearch.com/transparent-ceramics-market.html

Monochloroacetic Acid Market: https://www.transparencymarketresearch.com/monochloroacetic-acid-market.html

Transparent Ceramics Market: https://www.transparencymarketresearch.com/transparent-ceramics-market.html

Monochloroacetic Acid Market: https://www.transparencymarketresearch.com/monochloroacetic-acid-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com

Atil Chaudhari

Transparency Market Research Inc.

+1 518-618-1030

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.