Visible light writes hidden fluorescent patterns for anti-counterfeiting.

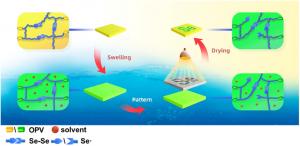

GA, UNITED STATES, January 15, 2026 /EINPresswire.com/ -- A new type of polymer material that can be patterned using gentle visible light, creating stable hidden images visible only under UV light. The method uses dynamic diselenide bonds and a swelling switch to enable rapid, precise patterning without damaging the material.

Inspired by the natural phenomenon of fluorescence, the field of fluorescent polymeric materials has recently garnered much attention, especially in the areas of including biological imaging, luminescent sensing, encryption, and anti-counterfeiting. The photopatterning strategy, as a crucial method for patterning such polymer materials, primarily relies on the structural changes of fluorescent molecules under ultraviolet (UV) irradiation. However, UV irradiation can be energetically demanding, potentially causing damage to the materials, and is limited by shallow penetration depth. Therefore, visible light emerges as a more favorable alternative for irradiation.

In a study published in the KeAi journal Supramolecular Materials, a group of researchers from Tsinghua University and Jiangnan University in China has created a new fluorescent material that can be patterned using only visible light—an advance that could improve anti-counterfeiting labels and secure information storage. The material contains dynamic diselenide bonds and fluorescent molecules that change color when exposed to visible light during a simple swelling process.

“Visible light is much gentler and can penetrate deeper, making it more suitable for real-world applications,” says Huaping Xu, a professor at Tsinghua University and one of the study's corresponding authors. “Our material can be patterned in just ten minutes using ordinary visible light sources like LEDs or even a projector.”

The key to the system is the use of diselenide bonds, which undergo dynamic exchange under visible light, relaxing internal stress in the polymer network. “When the material is swollen in solvent, fluorescent molecules shift from an aggregated state (orange emission) to a monomer state (green emission),” explains Xu. “Visible light irradiation locks in this color change in the exposed areas, creating a stable pattern that remains invisible under daylight but glows under UV light.”

According to senior and co-corresponding author Huaping Xu, their method is expected to provide new ideas for the manufacturing of fluorescent anti-counterfeiting labels. “The pattern is also very stable—it doesn't fade even after months of indoor or outdoor exposure,” says Xu.

Further, the team demonstrated the method by patterning QR codes, barcodes, and complex graphics onto polymer films and 3D shapes. “The approach could be used for high-security labels on pharmaceuticals, electronics, and official documents,” adds Xu.

DOI

10.1016/j.supmat.2025.100115

Original Source URL

https://doi.org/10.1016/j.supmat.2025.100115

Funding information

This work was financially supported by the National Natural Science Foundation of China (52233012). H. Xu also thanks the XPLORER PRIZE and the Beijing Out-standing Young Scientist Program.

Lucy Wang

BioDesign Research

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.